Corrugated iron rolling machine

The NAVAVINA shelf-mounted corrugated sheet rolling machine is manufactured and assembled in Vietnam, with control components imported from foreign countries such as Korea, Japan, Taiwan... The machine can roll all types of square, round, and 6 live, 9 live or according to customer's request

Navavina's corrugated iron rolling machine

Article content (Click to quickly view)

Introducing the corrugated iron rolling machine product

Navavina specializes in constructing all kinds of corrugated iron forming machines, with diverse designs, exact profiles according to customer requirements, can be installed to run a series of many sizes, using Square Wave corrugated iron rolling machines to shape various shapes. Corrugated iron sheets, types, combined with the Dome Bending Machine create the Dome Corrugated Iron.

– Rolling machine length: 6 – 8m

– Machine weight: 6 – 9 tons

– Number of shaft pairs: 16 – 18 (depending on profile)

– Rolling speed: 11 – 14m/min

Applications: rolling roofing sheets, wall panels, decorative panels and railings.

Commonly used types of corrugated iron rolling machines: 5-Wave Corrugated Iron Rolling Machine, 6-Wave Corrugated Iron Rolling Machine, 9-Wave Corrugated Iron Rolling Machine, 11-Wave Corrugated Iron Rolling Machine,

Why is a corrugated iron rolling machine a necessary product?

With the trend of economic development, changing needs and gradually developing technology, people's requirements are increasingly higher in terms of aesthetics, budget savings and investment time to choose processed corrugated iron sheets. and corrugated iron rolling technology.

The trend of changing corrugated iron rolling machines was born to meet consumer tastes. The corrugated iron roll forming machine solves difficulties according to customer criteria. Navavina corrugated iron factory has a variety of designs and beautiful shapes, which is a diverse choice for business customers.

Quality and reputable corrugated iron rolling machine

Reasons why Navavina corrugated iron rolling machine attracts businesses

Corrugated Roll Forming Machine has many designs. Currently, the 1-layer corrugated iron rolling machine is a product line of 4-wave roofing sheet rolling machine, 5-wave corrugated iron rolling machine, 6-wave corrugated iron rolling machine, 7-wave corrugated iron rolling machine, 9-wave corrugated iron rolling machine, 11-wave corrugated iron rolling machine and 13-wave corrugated iron ceiling cladding. corrugated iron rolling machine…

Each line of corrugated iron rolling machine will have its own distinct advantages and different parameters are clearly stated on the machine line. 2-tier corrugated iron rolling machine, liquidation of corrugated iron rolling machine, price list of corrugated iron rolling machine, old 2-tier corrugated iron rolling machine, old corrugated iron rolling machine, foam corrugated iron rolling machine, tile corrugated iron rolling machine, selling price of 2-tier corrugated iron rolling machine,

The variety of corrugated iron rolling machines today is an advantage for customers to choose from, how to choose an effective line of corrugated iron rolling machines.

The appropriate corrugated iron rolling machine depends entirely on the shape of the corrugated iron sheet we want. For example, if we want to own a corrugated corrugated iron sheet, we will choose a corrugated iron sheet rolling machine and will deform the flat diagonal shape according to For the type of corrugated iron you want, you can choose a corrugated sheet rolling machine, square or corrugated tile, straight or curved...

The important thing is to choose the type of corrugated iron according to your preference. The machine will automatically engrave the internal operating principle to create the desired and beautiful corrugated iron sheet without using too much labor at the same time.

In addition, Navina provides a line of 3-tier corrugated iron rolling machines:

Raw material thickness: 0.2 – 0.6 mm

Total electrical capacity: 10 HP

Rolling capacity: 15 - 20 m/min

Rolling shaft diameter: 70 mm

Number of axle pairs: 18 – 23

Length * Width * Height: 12m x 2m x 1.2m

Volume: 12 Ton Tons

Foam corrugated iron - PU corrugated iron rolling machine

The line sprays PU chemical mixture onto the corrugated iron surface to create brands of 3-layer corrugated iron, cooled corrugated iron, and PU corrugated iron

Corrugated iron heating: 14kw

Conveyor belt heating: 30kw

Rolling capacity: 7 - 15m/min

PU leprosy station: 5.5kw

Foam thickness: 20 ÷ 25 mm

Control system: Automatic

Conveyor drive: 7.5kw

Machine dimensions L x W x H: (18 ÷32) x 1.35 x 2.5m

Weight: 16000kg

PU corrugated iron rolling machine, 3-layer corrugated iron divided by machine length into 3 types:

– 18m foam corrugated iron rolling machine:

Advantages : foam corrugated iron rolling machine: machine has short size, low price, suitable for workshops with short length

Disadvantage : the machine's output speed is from 7m/min to 9.5m/min due to the short drying conveyor, the machine needs enough time to harden and dry the chemicals. . The speed of the 18m foam corrugated iron rolling machine is slow, leading to low productivity.

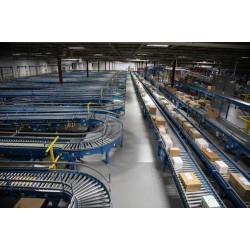

With more than 16 years of experience in the warehouse racking manufacturing industry, with a team of technical experts, highly skilled workers and a closed production line, we always advise, design and equip storage racking systems. products for businesses nationwide with the highest efficiency, reasonable costs and the most optimal solutions.

With a modern automatic production line factory, quality raw materials, abundant human resources, and a team of formally trained technical staff, we have created shelf products. and warehouse shelving solutions of outstanding quality, fully meeting international standards.

Corrugated iron rolling machine products

SELECTIVE STORAGE SHELVES

The Selective shelf system is designed for use in warehouses with continuous import and export needs, short storage times or storing many types of products in the same warehouse..

DOUBLE DEEP STORAGE SHELF

It is a type of warehouse shelf that holds 2 pallets of goods deep inside the shelf, increasing the capacity of goods. Created by two rows of double shelves back to back, the usable warehouse floor area increases.

DRIVE IN STORAGE SHELVES

This type of pallet storage rack has a high density of goods and is economically effective because it eliminates space for aisles. This is a very popular solution that HAIMY has designed for customers.

PALLET RACK STORAGE SHELF

In order to meet the storage solutions for pallet warehouse racking systems, we temporarily divide this product line into 2 types so that you can easily choose a solution for your warehouse.

NARROW AISLE & VNA SHELVES

This type of warehouse shelf is especially suitable for warehouses with high roofs and high storage capacity. In the storage rack solution, the forklift aisle is narrow and very narrow.

SHELVES DO NOT USE PALLETS

Warehouse racking system does not use pallets. This type of warehouse racking system is designed to meet the need to store products and goods without using pallets.

CANTILEVER SHELF

Navavina Rack arm-shaped storage shelves are designed to accommodate goods that are unstable in product length and size. This type of storage rack completely uses loading and unloading goods from the front.

SHELVING SHELVING SYSTEM

The Shelving warehouse racking system is a type of non-palletized storage racking that Navavina has largely supplied to the market for over 16 years. This Shelving shelf system from Navavina resembles the image of a shelf system

MOBILE SHELF

Mobile shelving storage system is a product that is widely used in social life, in the fields of production, business, commerce, etc. and for storing records and documents. , library…

MEZZANINE FLOOR SHELF SYSTEM

Navavina is designed according to American standards. Currently, this type of floor shelf system is a very popular solution in warehouse systems in the US. In Vietnam under conditions

AUTOMATIC STORAGE SHELVES

The automated shelf storage system is the most complex type of shelf designed to be applied to highly standardized warehouses, with extremely scientific warehouse management.

STACKED SHELVES

The stacking shelf system is a flexible solution for warehouses with a lot of space where fixed shelves cannot be installed, and for storing goods.

Navavina warehouse racking with more than 16 years of reputation leads the quality in the industry of warehouse racking, storage shelves, material handling equipment, and storage products. Our years of experience and expertise help us match customers with the right warehouse storage racks, pallet rack accessories, wire floors, industrial shelving and warehouse equipment.