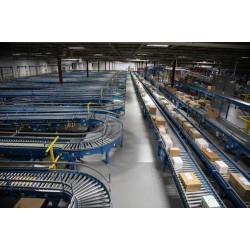

Automatic storage shelves

Automatic shelves and automatic sliding shelves have the advantage of an automatic import and export sliding shelf system, designed according to modern standards, goods are moved automatically through a conveyor system, saving money. Save time, costs and labor (investment, production, operation, labor) and ensure worker safety.

Navavina has more than 16 years of experience in designing and manufacturing automatic shelves for warehouse systems using pallets.

Automatic storage racking system

Article content (Click to quickly view)

Introducing AUTOMATIC STORAGE shelves

Automatic sliding shelves are the most complex type of shelf design intended to be used in warehouses with high standardization and scientific management. Currently, sliding shelves have successfully applied automation solutions in warehouse management.

Automatic storage shelves, also known as automatic sliding shelves, have become popular in Vietnam for warehouses due to the increasing need for warehouse storage along with warehouse preservation and storage.

The automatic shelf system and automatic sliding shelves solve the compact goods management process, first in terms of personnel, followed by efficiency in work and goods transfer. Navavina has more than 16 years of experience consulting, implementing and installing automatic sliding shelf systems to serve large projects.

Automatic storage shelves, automatic sliding shelves have 3 types of storage shelves commonly used in storing goods: Carton flow rack, Pallet flow rack, Push pack racking.

Outstanding advantages of automatic shelves

– Automatic shelves operate without the need for forklifts to load and unload goods, narrowing aisles and increasing warehouse usage area.

– Operates with plastic rollers.

– Increase warehouse storage area by up to 70%.

– Bearing load from 1000 – 3000kg.

– High storage efficiency, the system can store 2, 3 or 4 cartons on the same shelf at the same time.

- Durable.

– Suitable for warehouses with industrial goods, large warehouses, and quick goods movement time.

– Warehouse Storage Sliding Shelves

Advantages of automatic storage shelves

Sliding warehouse storage shelves are a shelf system designed to slope forward with rollers to allow pallets or cartons to slide automatically, helping to maximize time for picking up goods and optimize space. Warehouse storage space

Storage solution using Carton Flow racking system

This is the optimal warehouse storage solution for quick import and export needs, saving time picking up goods at the warehouse. Apply automatic conveyor belts to transport goods in the same direction without pallets in the racking system. Rollers are set up vertically and take advantage of gravity with a lower end to move goods. At the input, just put the goods up and the box will move inside with this method, the goods imported first will go out first.

Carton Flow shelves are used in dry or cool storage environments. Widely used in industrial warehouses, textiles, parts warehouses, electronics, auxiliary materials, food and pharmaceutical warehouses.

The most complex to apply to highly standardized warehouses, warehouse management is extremely scientific. In the world today, people have successfully applied automation solutions in warehouse management. Including warehouses that use pallets or do not use pallets,

Characteristics and features of Carton Flow shelves

– Steel alloy material, powder coating ensures the shelves will not rust in many usage environments.

– Solid pedestal design, close to the floor ensures the stability of the shelf. (Background shooting)

– Horizontal bars (veam DW) are able to bear heavy loads thanks to their special design.

– Load capacity from 1 ton – 3 tons

– Increased usable storage area because the aisles have been optimized without losing space.

Operating principle of Carton Flow Rack

The Carton flow rack sliding shelf system is a mobile storage solution. Each conveyor belt includes a series of rollers that follow high-quality cartons. The rollers are arranged in a row along the lower shelf, and gravity is used to move the carton from one place to another.

Use gravity conveyors to move boxes or trays of goods to one side (do not use pallets). When one carton is removed, the next carton is pushed further forward. Import and export goods according to the principle of first in, first out.

Carton Flow Rack structure

– Made of high quality iron and steel, electrostatically painted to prevent rust and metal corrosion.

– Omega pedestal structure (Ω) combines the base and the drilling platform switch directly to the warehouse floor to ensure high safety.

– DW beam design to withstand heavy loads.

– Cartons in the same compartment will be placed on sleds and they will slide all the way inside when loading goods. When taking goods out, the sleds will automatically move forward and fill the gap.

Structure of automatic storage shelves

Automatic sliding iron shelves for storing goods are designed as follows:

– Carton Flow Racking system

– 4-storey high shelf

– Has an automatic sliding roller design

– The height of the shelf is: 1.5m

– Load capacity 1000kg/floor

Navavina's Powder Coated Automatic Sliding Iron Shelf is being provided

Automatic sliding storage shelves are made of powder-coated iron installed by Navavina with dynamic storage solutions. The carton or plastic tray slides forward automatically. Optimally save labor, control goods easily, and prevent loss of goods. Long shelf life. Save investment costs significantly.

Automatic sliding shelves, sliding carton shelves, automatic shelves. With sliding wheels and rollers, goods automatically slide in one direction, reducing labor costs for transportation, loading and unloading. Less

Automatic sliding iron shelves containing powder-coated goods increase the storage area of goods by 70%, the load can be up to 1000kg/floor or more. Save time preparing for other orders.

Automatic sliding iron shelves containing powder-coated goods with a conveyor belt motion system thanks to rollers made of iron, called Carton Flow Rack installed by Navavina for Toshiba Asia Vietnam company under the project Raw material warehouse shelves have been a great success.