Sliding pallet shelves

The sliding pallet racking system is a solution for storing goods in warehouses with advanced technology that automatically synchronizes moving bars to move smoothly and professionally according to an assembled remote control system.

Article content (Click to quickly view)

Introducing PALLET SLIDING SHELVES

Depth can range from 2 to over 20 pallets deep, thus giving you higher storage density compared to other forms of shelving. Racking. Pallet racking, or flow, is a method of pallet storage that uses gravity flow, as well as wheels or rollers, to convey and accumulate pallets within the storage module.

With pallet flow racks, gravity flow pallet racks or other gravity flow rack systems, different forklift operators can load and unload pallets independently. Because pallets move from the loading end to the unloading end themselves, forklift travel is reduced. Industrial shelves.

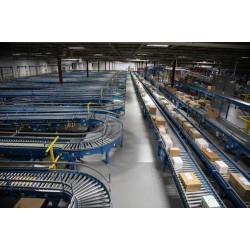

Flow storage consists of two elements: a static rack structure and dynamic flow rails. The conveyor belts in the warehouse move with a slope that creates a moving force for the pallets of goods. The goods will be rotated, making the import and export of goods extremely convenient according to the cycle when a pallet is loaded. When exported, there will be another pallet to fill that gap and be equipped with deceleration devices to adjust the moving speed of the pallets of goods.

The rails are a tracking/rolling system set in decline along the length of the rack. The wheel systems of the pallets are capable of bearing very large loads and are impact resistant when moving quickly, without any incidents occurring during the transportation of goods. The rails allow the load to move by gravity from the loading end to the unloading end.

The storage system only requires one aisle for loading and one aisle for unloading, allowing for the storage of multiple pallet loads back-to-back. Each lane includes a self-powered speed controller (brake) to gently control the speed of travel within the lane. As a result, flow systems can offset the need for new construction and reduce a range of operational costs such as forklifts, labor and energy.

Types of sliding shelves are popular today

Pallet Flow rack

When a load is removed, the loads behind it move back to the unloading position. This professional automatic sliding shelf system is designed according to international standards, making the storage of goods in warehouses convenient and simple, saving time and costs on warehouse management and maintenance. Protect goods safely, import and export quickly and conveniently.

The depth, height and width of the stream system are limited only by the size of your facility and the capabilities of your material handling equipment. Storage Racks Storage solutions are used in situations where storage density and inventory turnover are priorities.

Heavy duty shelves

Advantages of flow pricing system:

- Sliding pallet shelves for goods are made of high-quality, high-quality iron and steel materials. Provides high density storage.

- The entire product is electrostatically painted to prevent rust, metal corrosion, and is highly durable. First-in-first-out (FIFO) inventory control, with automatic inventory rotation

- The omega (Ω) pedestal structure combines the base and the base block to drill directly into the warehouse floor, ensuring high safety.

- DW beam bar design withstands heavy loads. Best for storing similar items and items in large quantities

- No need for forklifts to load and unload goods, narrowing aisles and increasing usable area.

- Increase storage area by 70%.

- Load capacity from 1000 - 3000kg.

- The two functions of importing goods and receiving goods can be performed at the same time without affecting each other. Forms dynamic flow rail and static rack structure

- Commonly used in industrial warehouses, textiles, parts warehouses, electronics, auxiliary materials, food and pharmaceutical warehouses.

=> Pallet sliding shelves easily track and control inventory. Save time, costs and labor.

Flow storage is specifically designed for first in, first out (FIFO) pallet storage. The traffic storage system is based on two parts:

- Dynamic elements help move products down the lane

- Static elements provide physical support for the system

Automatic sliding pallet racking system

The load is transported, via rails that flow from the loading end to the unloading end of the storage system. The first load is always the first load given. Industrial shelves. Single-directional sliding shelf system (Pallet Flow Rack) is a system designed according to the conveyor motion technique with a slope that creates the force of movement of pallets in one direction.

This constant stock turnover is especially beneficial with perishable or time-sensitive goods, such as food or pharmaceuticals, where lost product becomes lost profit. Flow storage systems are considered high density storage systems because of their ability to store more pallet loads in the same space than standard select rack systems.

Reduces the cost of handling equipment that can be used in dry, frozen or cooled storage environments. This solution is often applied to warehouses with products of the same type such as food that do not require forklifts. specialized goods.

Used to increase picking efficiency on the first-in, first-out (FIFO) principle. Import and export goods according to categories automatically – forklifts do not have to move deep into the system. Higher basic investment compared to shelves of the same type (such as Push Back, Drive in/Thru,...).

Arrangements can be designed from 2 pallets to 20 pallets according to the depth of the system. Arrangements can be designed from 2 pallets to 20 pallets according to the depth of the system. Arrangements can be designed from 2 pallets to 20 pallets. pallets according to the depth of the system. Installation adjustment is more difficult

Sliding carton flow rack

Forklifts are only required for initial loading and final unloading. Because only two aisles are needed, aisle space can be reduced by 75 percent. The dynamic elements of a flow storage system consist of various wheel or roller components installed in a reduced frame to move pallet loads from the high end of the flow system to the opposite end using gravity. force.

Fewer elevators, operating fewer hours and consuming less fuel can perform the same handling function.

Save time and labor.

With only two aisles, each dedicated to specific functions (loading or unloading), traffic flows more orderly, staff is more efficient, and overall productivity is improved.

The Flowrack racking system is often used in warehouses with large quantities of goods that must be imported and exported in a first-in-first-out direction. The pallets containing goods will be placed on ramps and slid on rollers. Brakes are sometimes placed at different intervals in the rail system to keep pallets moving at a controlled speed, protecting pallets and pallet loads from overshooting and impacting each other, causing product damage.

When a pallet is removed, the next pallet automatically fills the space with replenishment from the other end of the shelf. The pallets automatically follow each other so they can take advantage of the empty space, the stored goods will rotate for export. Pallet speed is controlled by deceleration devices.

Save space because storage density can be doubled, storage capacity can be increased within the same storage area, or part of your existing storage area can be provisioned for other uses. Long shelf shelving is the ideal solution for carton type storage with manual handling, cost savings and easy assembly and disassembly.

Save on construction costs By increasing storage capacity in existing facilities, the need for new construction can be eliminated. Also it allows adding or removing price levels and unit quantities, and according to height differences in different locations of the same warehouse, shelf heights can be designed with different heights, it will provide max.

The utility of warehouse space is warehouse shelves. When new construction is necessary, construction size and costs can be reduced by up to 50%. A smaller warehouse area, in turn, can reduce insurance, land acquisition costs and taxes. After you move your warehouse, the shelves can be moved together. It is especially practical for storing lost SKUs and small quantities and frequent logistics traffic.

Reduced operating costs Higher density storage and therefore smaller storage areas also mean less area for heating, lighting, air conditioning and/or refrigeration. A wide range of accessories is available for all types of applications with different storage unit sizes. Reduced fork lifting damage Reducing step lifting loads can result in less product loss and less potential for impact damage to the rack structure. Pallet flow storage systems use a combination of raised rails and moving components (wheels, rollers, conveyors) in a rack-supported structure.

Flexibility in Storage Storage storage systems have been successfully installed as part of virtually every storage function, including material receiving and storage, work in process, buffer storage , finished goods, order picking and cross-assembly. Flow systems put the power of gravity to work. Pallets are loaded at the high end of the rolling lane and moved towards the other end by gravity where they are ready to be unloaded.

Push Back Racking System

Pallet entry guides can be used to help warehouse staff position pallets correctly within the rail system. Pallet ramps are also available at the exit end of each lane to reduce final impact and help bring pallet loads to a gentle stop.

Hardware: SK3400 uprights

- Continuously welded, all pipe construction has greater durability and is environmentally hygienic, with little maintenance

- Tubular column, 3" x 3", 55,000 PSI steel, multi-gauge. This meets many needs for capacity and durability

- The heavy duty bolt connection allows for a secure, slip-free connection – it is also adjustable

- Holes on the face (not corner) of the column, to minimize column strength

- Forming ridge columns – means increasing column stiffness

- Full horizontal welds for increased impact resistance.

- Horizontal and diagonal bracing increases frame strength

- The 10-gauge heavy-duty trackpad disperses the floor load.

- Footpad ridge for easy “shim” nesting.

- Table legs flow easily for easy “beam floor” seating

- Multiple “offset” anchor holes for easy anchor attachment.

Tracks, wheels and braking system

- Full selection of wheel and roller configurations, so our racks handle virtually every type of pallet or skid

- Unassisted, indirectly mounted brakes for smooth and reliable speed control

- Fully tested components, customized for your operation

- The exit beam will act as a pallet stop, so pallet pressure is evenly distributed

Why should you use Pallet Flow Racks

Pallet flow (with gravity flow rack system) technology is often associated with high volume products; they can be found primarily in manufacturing environments where multiple pallets of the same item are produced. Warehouse Racking Others will use flowrack to stage order for shipments, or in picking systems to store pallet loads of goods for high volume picking situations.

CONTACT US

- Branch 1: 1330/1D Vuon Lai Street, Quarter 1, An Phu Dong Ward, District 12, HCMC

- Branch 2: Land plot 981, map sheet 40, Binh Dang Quarter, Binh Hoa Ward, Thuan An City, Binh Duong Province, Vietnam

- Phone number: 0274 379 7667

- Hotline: 0385 848 168 – 0384 948 168 – 0386 048 168

- Email: sales@navavina.com.vn

- Website: https://navavina.com

- Fanpage: https://www.facebook.com/navavinagroup