Carton flow rack

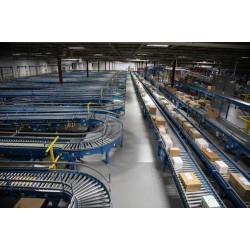

Carton flow rack with the name flow shelf, sliding shelf is used in industrial warehouses, manufacturing workshops, general warehouses, places to store goods, warehouses, etc. shelves are installed flexibly, Simple support bars directly on the rail help prevent goods from being thrown out when sliding on the shelf, ensuring a consistent sliding path to the other end.

Carton Flow rack shelf system

Article content (Click to quickly view)

Introducing CARTON FLOW RACK

Carton Flow Rack system, a dynamic storage solution (Live Storage) of Navavina, is designed according to the sloping conveyor motion technique that creates the moving force of boxes or trays of goods moving to one side ( do not use pallets).

Carton Flow shelves are commonly used in commodity centers, multi-purpose storage centers... there are many types of goods but the quantity that needs to be stored is not large or the goods must apply import and export principles in the direction of import and export. goods. Containers or shelves automatically line each other so they can take advantage of empty space, and stored goods will be rotated for export.

Working principle of Carton flow rack

Carton Flow storage shelves are designed with multiple floors, with many products that support sliding on rails: cabin boxes, carton boxes... without using Pallets. Multi-tiered shelves take advantage of available height in the warehouse to optimize higher storage space.

Working principle of carton flow rack

Containers or trays will be placed on ramps and slid on rollers. When a box or tray is removed, the next box or tray will automatically fill the space with replenishment from the other end of the shelf. Travel speed is controlled by deceleration devices.

Technical characteristics of Carton Flow Racking shelves

This solution is often applied to warehouses with many types of products such as spare parts, food, pharmaceuticals...

This type of shelf is often used in dry or cool storage environments

Used to increase the efficiency of product selection on the principle of import and export of goods. The layout can be designed according to goods storage requirements

No need for forklifts to load and unload goods

Storage shelves and warehouse shelves are designed in the form of industrial storage shelves (Carton Flow racking). The entire shelf system is powder-coated according to industrial standards. The storage rack system has been accepted, handed over and put into use, meeting the following technical specifications:

– Carton Flow Racking system

– 6-storey high shelf

– Has an automatic sliding roller design

– Height of shelves is: 2.5m x Length 15m x Width 2m: 10 rows

– Load capacity 1000kg/floor

Carton Flow Rack Racking Systems for every size warehouse and every shelving range are gravity oriented and perfect for applications with multiple SKUs. Separating the loading aisle from the retrieval aisle allows the selector to operate more efficiently. Carton Flow Rack uses tilted shelves to improve visibility and order accuracy and is the perfect answer for portioning or partial picking.

Carton Flow Rack

Other carton rack options, such as impact floors and intermediate supports, can help protect against warehouse abuse and extend the life of the system. Carton Flow Rack can be integrated with conveyors and other warehouse solutions to create functional and efficient picking modules.

Navavina manufactures a wide range of carton racks – traditional roller tracks including UPICK knock-up designs, KPICK racks (Kingway carton flow racks) or RhinoTrac full width racks in roller units and concentric storage systems, CSS, DuraFlo and D2 carton thread lanes.

Navavina's Carton Flow Rack system

The Navavina Carton Flow Rack system makes transporting and installing even the most complex modules simple. Trax steel cartons are installed easily and are available on 3 hubs. Interchangeable front/rear assemblies and side members make ordering and installation less confusing. Vertical 1-1/2 shelf adjustment allows for easy configuration and system flexibility.

RhinoTrac full-width flow roller conveyors are a more durable solution than traditional carton flow for warehouses storing heavy product flow. Pre-assembled lanes with integrated supports are simply placed into brackets and rest on beams.

Navavina industrial iron shelves are an option for lighter duty products or as a retrofit to existing Carton Flow Rack installations.

Carton Flow Rack can significantly improve warehouse efficiency by organizing products and rotating automatically. Long, straight, dedicated lanes maintain product organization and reduce labor costs. Storage space can be increased by up to 60% by using at least 22% less floor area, thus helping to reduce construction costs.

Typically, carton rack systems use about half the floor space that standard pallet racks do, and the difference can be more dramatic with multi-level systems. The simplicity of gravity-driven systems requires less capital than maintenance-automated systems.

Carton Flow Rack warehouse system that Navavina is providing

Our carton rack system for sale offers high capacity and high durability. There are many custom sizes and configurations available. Contact us to speak with an engineer and design your pricing solution today.

Carton Flow

Flow Bed creates an adequate level of carton flow. This provides maximum flexibility to place the product in any location within the carton flow system without the need to change/move equipment. The Flow Bed's drop-down design fits into any pallet rack structure making it easy to transition from static to dynamic storage that delivers all the benefits of carton flow.

Carton flow rack is one of many places in the material handling world where gravity is used to assist in the transportation of products. Carton flow uses a series of rollers or slightly damped sliding wheels to provide a steady, efficient supply of product to an employee selecting products for various applications.

Loading products from the back of the shelf and picking from the front allows employees to work simultaneously, keeping all products stored on the shelf without ever crossing paths, in some cases allowing for increased Yield up to 75%. Thanks to the constant flow of product to the front of the shelf, the carton flow provides condensed product storage that after the first pass in the first product rotation keeps each product on the shelf for the shortest possible time. maybe.

There are different types of carton racks, and each has distinct advantages and disadvantages depending on the products that will be in the system and how the system will be implemented.

- Full roller width

- Skate wheel rack

- Full width skate wheel rack

Full width roller flow racks provide the ability to drop into existing pallet rack beams and create lanes of rollers that span the entire width of a bay.

If you plan on using pick trays, totes, or any other product with little to no size variation in your system, full-width rollers are a great long-term choice. The disadvantages of full width rollers come from the fact that you are limited to each lane of the roller and cannot adapt if your container changes.

Rail lane

Rail rails provide the ability to fall into existing pallet rack beams and consist of 2 or 3 rails positioned based on the size of the containers. These rollers can easily be reconfigured for new products and lane widths. These tracks are typically cheaper than full-width rollers but tend to require more maintenance and do not provide as good product tracking

Full-width sliding wheels

The full-width wheel skid rack provides the ability to handle products of varying sizes without the need for reconfiguration as required. This provides additional upfront costs but allows for space optimization regardless of how your product dimensions change over time.

Tilted shelves

Any carton flow method can be enhanced to select separation cases with the addition of a tilt rack at the end of the lane. This allows operators to quickly and efficiently identify the product they are looking for and move on to their next task.